There are actually two Cameron models but the first one was released in 1937 and produced through 1940.

The Cameron comes in a solid 14K gold case and depending upon the year, both white or yellow (natural) gold was offered. Only one dial was available, the sterling silver dial with solid 18K gold applied numerals.

I recently received a Cameron in need of some tender loving care. It came on an old expansion bracelet - which wasn't original to the watch so it will have to go. I don't care for bracelets because they tend to wear into the watch lugs if they're not a perfect fit (and even if they are).

The dial is very dirty and based on it's looks I can't really tell if it's original or a very old refinish. The mottled patina in the field makes me wonder if the watch was attached to a smoker's wrist - maybe it's just nicotine and will clean off?

With the dial removed, there are no marks on the reverse and it looks untouched - so I'm going to say this dial is an original. That's good, because original dials usually clean up better than a refinished dial.

The 19 jewel 982 movement is correct for the watch and the serial number dates to 1938, perfect for a Cameron.

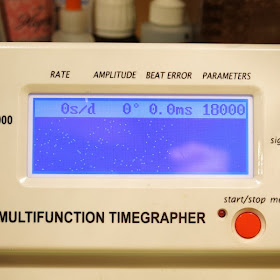

Although the watch is running, it's running very poorly. With the watch on my timer you can see the tell tale sign of a shot-gun pattern of noise. It should be two lines, fairly close together. So this watch really needs help.

Uh oh - this model happens to have female spring bars. That means there are pins in the lugs, as opposed to holes. Replacing these spring bars is a challenge as the holes in new spring bars are usually too small and need to be enlarged to accommodate the size of the male pins.

Here's a shot of the pins. The female bar will fit between the pins and then expand over them to secure the new strap.

Sometimes you get lucky and can reuse the old spring bars. But not this time, these spring bars are shot. I wouldn't risk a valuable watch to potentially falling off because of worn out spring bars.

While everything is being cleaned in the ultrasonic, I'll turn my attention to the case and replacing the crystal. First, I'll polish the case.

With the case all spiffed up, a new glass crystal will be fitted for the bezel and glued in place with UV glue.

Not surprising, the mainspring is set - it's in a coil about the size of a nickel. A new mainspring will dramatically energize this 76 year old watch.

My first choice for mainsprings is a white alloy (unbreakable) Dynavar spring.

Everything is cleaned and dried so all that's left is to reassemble everything.

A good cleaning returned the watch to vigorous life. It's running a little fast right out of the chute but a little tweaking to the regulator will slow it down.

Here, from right to left, you can see the effect of my moving the regulator as the slope of the two lines slowly moves towards horizontal. Gone is the shot gun pattern - thank goodness! 23 seconds fast per day is a good set point for now. It will probably settle in as it runs longer.

Now that I know the watch runs properly I can move on to the final task of modifying new spring bars to fit over the male pins.

And here's the finished product paired with a new old stock vintage Hamilton pigskin strap, just like what would have come on the watch in 1938 (as shown in the catalog image above). The dial cleaned up very nicely, I think.

This watch is ready for another 76 years of faithful service!