One of the most common questions I get asked is, "Do you work on watches other than Hamilton?".

I do, but I don't. How's that for an answer. In my personal collection I have lots of different manufacturers and truth be told, I'm a sucker for a nice Omega in need of TLC. However, having original and correct parts is very important for Omegas and buying said parts is crazy expensive. For example, many vintage Omegas have the Omega symbol in the center of the crystal. It's a really cool detail but you're looking at $80+ for a correct crystal. Crowns are the same story.

I've worked on all of the major vintage brands... Waltham, Illinois, Hampden, Benrus, Elgin, Gruen, et al. In fact, the very first watch I serviced was my Great Grandfather's New York Standard pocket watch.

So why don't I work on all things watch-related? Parts is mainly the issue. Not wheels and such, as that could be an issue, but things like screws, springs, and other tiny parts that have a knack for "disappearing" if you're not super careful. I hate having to buy a donor movement simply to get the correct screw or spring I lost.

Then, it's a matter of knowing what is what. If the mainspring is broken, what is the correct replacement? What about the correct stem, hand sizes, etc. etc.?

I chose to specialize in Hamiltons because they were the best that American watchmaking had to offer. They were also the last to close their production doors in the USA. Lastly, there are over a thousand different models - so there is plenty to keep me busy.

I was recently asked to take on a vintage Gruen and I begrudgingly agreed - mainly thinking it would be a 1950's era model, which isn't too different than a Hamilton from the same time period.

Turns out it is much older. So I thought I'd show you what it's like... what's different, what's similar, and you can see for yourself.

The Gruen Watch Makers Guild was started in 1894 - just after Hamilton was formed. It was headquartered in Cincinnati, OH. It was one of the first US watch companies to utilize Swiss-made ebauches as the basis for their models. Hamilton eventually did the same, about 30 years later, but most Gruen movements I've come across have "made in Switzerland" on them.

I really don't know that much about the history of the Gruen Watch Company. Most of the models I've seen are from the 1940s and 1950s like the Veri-thin line. Eventually they closed their shutters in 1958 but I think the brand name may still be around.

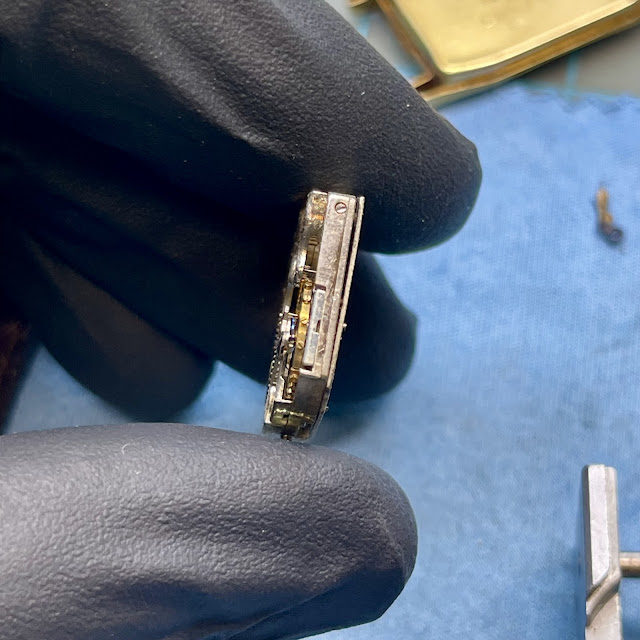

My project watch was a surprise to me... I'd say its from the 1930s or perhaps a little earlier. It's a tank-style watch - very 1930's to my eye.

The case is a two-piece design with an engraved front bezel and deep case back to secure the movement. The engraving echos details of a 1920s model.

The first interesting thing I see is the lugs - check them out - they are hollow! The spring bars for the straps go through both sides. Even the case back has a hollow area corresponding to the lugs. If this was a Hamilton case, those lugs would be solid.

The inside of the case back is clearly marked Gruen and 14K. This is an interesting design - almost a case inside a case. There are quite a few previous watch makers marks inside, I'd say at least a dozen. This was a well cared for watch.

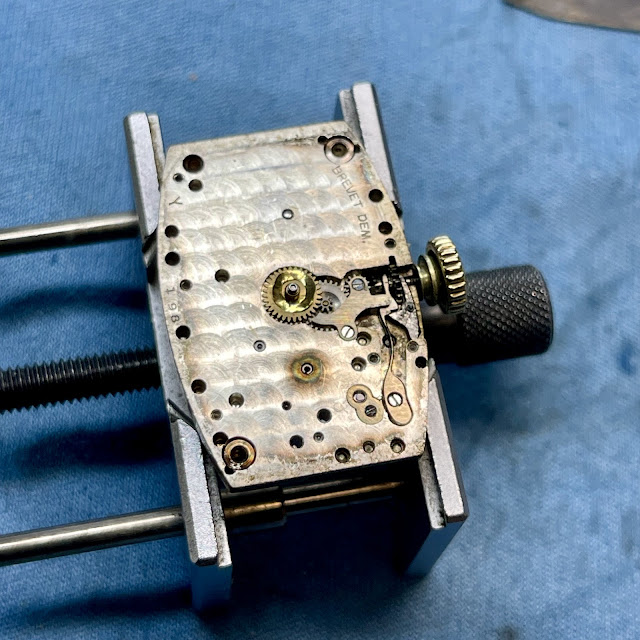

The movement is a Greun 157. I'm not sure what size it is but it appears to be a 12/0 sized movement as it's slightly larger than a Hamilton 14/0 980 / 982. Notice it's marked 15 jewels. Hamilton didn't make any wrist watches with fewer than 17 jewels. A watch is considered "fully jeweled" at 15 but where the 15 are can vary. Typically it's not jeweled at the center - meaning the center wheel is riding in bushings and not a jewel. You can see that is the case below. I guess because the center wheel moves so slowly (one rotation per hour), there's not as much wear as in the other faster moving wheels.

This movement is fully wound but not running. I don't see anything obviously wrong so hopefully it just needs a good cleaning.

There are two dial foot screws, one on each end. I can loosen them and lift the dial straight off.

There are several marks scratched into the back of the dial indicating it's been refinished at least one time over the last 90 years. The dial is also stamped 157 - I assume that's to indicate what movement it's intended to be used with.

The dial side of the main plate is a little cruder than what you'd see with a Hamilton movement but all the parts are essentially the same.

My tweezers are pointing at the pallet fork. This is a very unusual design. Normally the pallet fork looks like an anchor. However, in this movement it's shaped more like a backwards "F". The pallet fork has it's own bridge, as does the escape wheel, as does the 4th wheel (that the second hand attaches to). The center wheel and third wheel share a train bridge. I have to pay close attention to how the wheels stack, as I'll have to put them back in the same manner.

I let the mainspring down and can start stripping parts from the watch.

Here's another view of the pallet fork. What a funny design!

Everything is cleaned and dried - just like a Hamilton. All the parts sparkle a lot more but the nickel plating isn't quite as lustrous as your typical Hamilton movement.

Getting all the train wheels installed was a little harder than I thought it was going to be. All the wheels spin freely now so that a good sign.

The reassembled movement is ticking away with a nice motion. It's off to the timer to listen to the ticking.

Not too shabby - it's a little fast but otherwise looks fine. The regulator is already set towards the slow side but I can tweak it a little further.

I'll leave it running 23 seconds fast per day - that's totally fine for a watch from this era.

The finished watch looks pretty much the same as when it arrived but now it's running nicely. It's a nice watch but I'll stick with my Hamiltons - thanks just the same.

Amazing job..thanks for lot losing any screws :).

ReplyDeleteHello. How may we contact you? I recently inherited 2 vintage hamiltons and have several questions. Thank you

ReplyDeleteI have a vintage Hamilton tank watch I would really wish for you to look at.

ReplyDeleteIt’s to be a very special gift to our son for his Lt. Col promotion. It would mean the world to him for what it represents and the meaning of the Greatest Generation.

Can I email you details?

Thank you

A

Sure. You can email me via Instagram, Etsy, or vintagehamiltonrestoration @ gmail.com

Delete